Sludge and water treatment pump

In the water treatment sector, pumps play a fundamental role in the management of clean, waste and contaminated water, ensuring safe and efficient processes.

Fluimac pumping solutions are ideal for numerous applications, including tank filling and emptying, recirculating and purifying water within systems, and dosing chemicals such as sodium hypochlorite, ferric chloride, or polyelectrolytes.

Thanks to the resistance of the materials used, these pumps are perfect for handling chemically aggressive, abrasive fluids or ones containing suspended solids, such as sludge or filaments derived from production processes.

The excellent versatility of Fluimac pumps allows them to be adapted to neutralisation, purification and filtration systems, and cleaning or recovery operations, contributing to compliance with environmental regulations and the efficiency of industrial processes. The modular configurations and wide range of materials available for fluid-contact parts ensure compatibility with a wide range of substances, including highly corrosive solutions and solid particles.

Use of Fluimac pumps to extract water and sludge

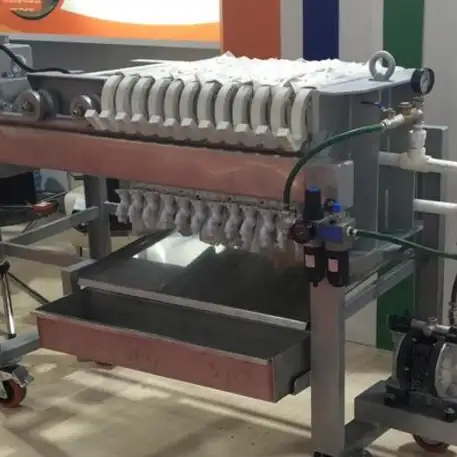

A specific sector, such as water treatment, poses several challenges including the transfer of acidic and alkaline fluids, chemical and abrasive sludge and the handling of fluids with suspended solids to ensure system efficiency. To best support these needs, the hallmark feature of Fluimac’s water and sludge extraction pumps is their reliability and versatility, providing optimal support for highly complex and ad hoc operations such as wastewater pumps, tank filling and filter-press feeding.

Thanks to an innovative design and high quality materials such as stainless steel, PP and PVD, the Fluimac range of diaphragm pumps allows the handling of highly corrosive or abrasive fluids with uncompromising performance. This makes dense sludge pumps ideal for applications where aggressive chemicals or pollutant-laden waters need to be transferred. These pumps guarantee long-lasting performance even in the most critical conditions of use thanks to their sturdy construction.

Request a free consultation by the Fluimac team to learn more about wastewater treatment pumps and identify the fluid handling solution that best suits your needs. You will be provided with all the technical details and specifications you need to find the best solution for your system.

Benefits of using fluid handling solutions for the water treatment industry

- Reliability and versatility

- High-quality materials

- Efficiency and cost reduction

Fluimac pumps for the water and sludge sector

Fluimac Dragon centrifugal pumps with mechanical seals are designed to meet the requirements of the water treatment industry, ensuring efficiency and reliability in the handling of clean fluids.

Thanks to the semi-open impeller and sturdy construction in resistant materials, such as PP and PVDF, Dragon pumps are ideal for transferring wastewater.

The virgin PTFE mechanical seal ensures corrosion resistance, preventing leaks and ensuring maximum safety during purification, neutralisation and recirculation processes.

Fluimac Typhoon vertical centrifugal pumps are designed to ensure high performance and reliability in the water treatment industry, offering ideal solutions for the handling of clean, wastewater fluids.

Thanks to their vertical design, Typhoon pumps are perfect for direct installation in tanks and reservoirs, optimising processes such as recirculation, drainage and purification.

Manufacture from corrosion-resistant materials, such as PP and PVDF, ensures a long life even in aggressive environments, making them ideal for the handling of chemically contaminated water.

Fluimac’s Compass magnetic drive centrifugal pumps are the ideal solution for water treatment, designed to ensure safety, reliability and high performance in the handling of chemically aggressive fluids.

Thanks to the total absence of mechanical seals, the hermetic design of the Compass pump eliminates the risk of leaks and minimises emissions, making it perfect for the transfer of wastewater, acidic and alkaline solutions, and other substances used in purification and neutralisation processes.

Compass pumps are an excellent choice for optimising water treatment processes, combining reliability, precision and sustainability, to ensure compliance with environmental regulations and improve the operational efficiency of systems.

Fluimac’s Phoenix diaphragm pumps are designed to meet the challenges of the water treatment industry, ensuring safety, reliability and high performance in the handling of chemically aggressive fluids, abrasives or those containing suspended solids.

Thanks to their sturdy construction and durable materials such as PP, PVDF, PTFE, Aluminium and AISI 316 steel, Phoenix pumps ensure compatibility with a wide range of fluids, making them ideal for applications such as chemical dosing, recirculation, drainage and water purification.

Phoenix pumps offer a reliable and flexible solution to optimise water treatment processes, ensuring operational efficiency and compliance with environmental regulations.

Applications

- Tank filling and emptying

- Recycling and water filtration

- Chemical dosing

- Emptying and drainage of wells

- Press filters

- Handling of sludge and liquids with suspended solids

- Wastewater treatment and recovery separation and filtration of oils and contaminants

- Neutralization and correction of pH

Reasons for choosing Fluimac

High-quality materials

Fluimac pumps are made of corrosion-resistant materials and are compatible with aggressive, abrasive or contaminated fluids, ensuring reliable and long-lasting performance. Manufacture from PP, PVDF and AISI 316 steel ensures maximum chemical and mechanical resistance.Safety and reliability

Designed to operate in critical environments, Fluimac pumps offer maximum safety in the management of wastewater, sludge and chemicals, preventing leaks and ensuring the integrity of treatment processes.Precision dosing

Fluimac pumps ensure precision dosing of chemicals such as sodium hypochlorite and ferric chloride, which are essential for water treatment, contributing to precise and controlled process management.Efficiency and speed

Our pumps are designed to ensure operational continuity, with a constant and optimised flow even in the most challenging applications. Easy installation and maintenance allow quick interventions and reduced downtime.Resistance and care in handling

Fluimac pumps effectively handle fluids containing solid particles, sludge and chemically contaminated water, ensuring high performance even in complex operating conditions.Request a consultation

Do you need help in choosing the best pump for your specific fluid handling needs?

Fill in the form below and you will be contacted by our staff.

The best solutions, certified