Pumping solutions for the pharmaceutical industry

In the pharmaceutical sector, companies need to handle delicate fluids such as medicines and sensitive chemical components.

This process requires careful management to avoid contamination and ensure the quality of the final product.

Among the main objectives of the pumps used in this sector are precision, compliance with high safety standards, full regulatory compliance and the absence of materials that can lead to impurities.

Use of ATEX Fluimac pumps in the pharmaceutical sector

The pharmaceutical industry requires stringent standards for the handling of delicate fluids such as medicinal solutions, sensitive chemical components and active substances. Specific products such as the Fluimac ATEX-certified pump and PTFE pump are cutting-edge solutions in this context, designed to ensure maximum reliability and operational safety.

One of the main challenges in this sector is the need to avoid contamination. Many materials used for the construction of pumps, such as some glass-filled plastics to improve rigidity, are not acceptable in the pharmaceutical field. Fluimac pumps, on the other hand, are available in materials that are fully compatible with the required purity requirements, such as PTFE (Polytetrafluoroethylene), a material that ensures chemical resistance and the integrity of the treated product.

In addition, in this particular sector, pumps must often be assembled in clean rooms, i.e. sterile environments that avoid any type of contamination during the production process. Fluimac is among the few players worldwide that can provide this option, positioning itself as an ideal partner for high-level pharmaceutical and chemical companies.

Fluimac ATEX-certified pumps, designed to operate in environments at risk of explosion, are a safe and reliable choice for the handling of corrosive and delicate fluids, thus ensuring compliance with both ATEX directives and the most stringent technical requirements.

Benefits of using customised fluid-handling solutions for the pharmaceutical industry

- Customisation Customisation is a crucial aspect in the pharmaceutical industry, where each system may require unique configurations to meet specific needs. Fluid-handling solutions offered by Fluimac allow a high degree of customisation, including options such as the type of attachment, size, flow capacity and construction materials. This flexibility allows our customers to obtain custom-made pumps, guaranteeing optimal performance at all stages of the production process.

- Reliability A further benefit is the reliability of Fluimac pumps, which combines simple maintenance with low operating costs, an aspect that is particularly relevant for companies with high production volumes. The construction quality and resistant materials, such as PTFE and other anti-corrosion compounds, ensure a long service life and a decrease in system downtime.

- Quality and safety In addition, Fluimac’s experience in the design of pneumatic and peristaltic pumps for the pharmaceutical sector allows it to handle even the most complex fluids, including suspended solids and highly corrosive chemicals. This makes their chemical, peristaltic and pneumatic pump solutions ideal not only for pharmaceutical production, but also for research and development applications, where precision and safety are imperative. Not to mention the overall quality of the construction components for unsurpassed safety in use and reduced maintenance costs.

- Specialised and dedicated assistance Fluimac also stands out for its after-sales service, offering qualified technical support and fast response times, fundamental aspects for the industrial sectors and the pharmaceutical sector. Thanks to this combination of quality, reliability and customisation, the company is positioned as a market leader and trusted partner for all fluid handling needs in the pharmaceutical industry.

Fluimac pumps for the pharmaceutical sector

Fluimac offers a range of pumps designed specifically to meet the challenges of the pharmaceutical industry.

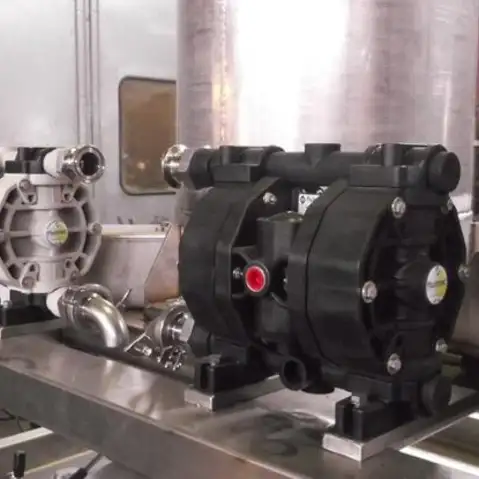

LOTUS diaphragm pumps are designed to meet the needs of the pharmaceutical industry, ensuring the safe and sterile transfer of essential chemicals in drug manufacturing. Made from the highest quality materials, including PTFE, conductive PTFE, PE, conductive PE and pure polypropylene, they ensure high purity and contamination prevention during critical processes such as fluid transfer, water treatment, cleaning and sanitisation operations, and precise handling of pharmaceutical components.

The sturdy construction of LOTUS AODD pumps, obtained by CNC machining of solid blocks, offers precise tolerances, a reduction in vibrations and increase in overall stability and durability. This structural solidity, combined with the use of resistant materials, allows the pumps to operate effectively even in difficult environments, minimising the need for maintenance.

LOTUS pumps are a reliable and safe solution for pharmaceutical applications, ensuring precision and reliability in sensitive production processes.

Fluimac’s Phoenix ATEX and Phoenix Steel diaphragm pumps are designed to meet the needs of the pharmaceutical industry, ensuring safety, efficiency and compliance with current regulations.

Phoenix ATEX pumps are made of materials such as PP+CF, PVDF+CF, POMc+CF, Aluminium and AISI 316 steel, offering a wide choice of flow rates and materials based on the specific needs and fluids used. These pumps are certified according to DIRECTIVE 2014/34/EU, UNI CEI EN ISO 80079-36:2016 and UNI CEI EN ISO 80079-37:2016, making them ideal for operating in environments with explosive atmospheres consisting of gases and dust. The double diaphragm design enables dry operation without damaging the pumping system, with a dry extraction capacity of up to 6 metres. In addition, the Phoenix ATEX AODD pumps allows the transit of liquids with solid particles and can be fully immersed, while always considering the compatibility of the fluid.

Phoenix Steel pumps, with an AISI 316 stainless steel central body, are ideal for transferring corrosive liquid substances, solvents and chemicals used in water treatment. The AISI 316 stainless steel construction guarantees corrosion resistance, durability and versatility, making them suitable for continuous operations and in highly humid environments where thorough cleaning is required. These AODD pumps can handle viscous substances and suspended solids without damage, thus ensuring long life and reliability, reducing downtime and maintenance costs. The design allows dry operation, they are self-priming with a dry extraction capacity up to 6 metres with complete immersion, while always considering the compatibility of the fluid.

Fluimac’s Helios peristaltic pumps are designed to meet the specific needs of the pharmaceutical industry, where safety, precision and sterility of processes are paramount.

Thanks to the peristaltic operating principle, Helios pumps ensure delicate and contamination-free handling, ideal for the transfer of sensitive or viscous fluids, or ones containing solid particles in suspension. This type of operation avoids direct contact between the fluid and the mechanical parts of the pump, thus ensuring the purity of the treated product.

- Standard-compliant materials:: Helios pumps are made of materials that are suitable for pharmaceutical processes and can be easily integrated into CIP/SIP cleaning and sterilisation cycles.

- Accurate dosing:: they ensure accurate control of the fluid, essential in drug production processes.

- Ease of maintenance: the hose is the only component in contact with the fluid, simplifying replacement and sanitisation operations.

- Versatility: suitable for the transfer of saline solutions, pharmaceutical suspensions, gels and other fluids with variable viscosity.

Applications

- Press filter

- Tank emptying

- Large-scale transfers

- Dosage

Reasons for choosing Fluimac

High-quality materials

Fluimac pumps are manufactured from materials that comply with international quality standards, guaranteeing resistance and durability, even with sensitive and high-value fluids.Safety and Compliance

Fluimac pumps comply with safety and quality regulations, including FDA, ATEX and MOCA, ensuring reliability and safety in pharmaceutical applications.Innovation and reliability

Fluimac constantly invests in research and development to offer cutting-edge solutions that meet the specific needs of the pharmaceutical sector.Performance and maintenance

Fluimac pumps are designed to deliver high performance with minimal maintenance, thanks to a modular structure and high-quality components.Request a consultation

Do you need help in choosing the best pump for your specific fluid handling needs?

Fill in the form below and you will be contacted by our staff.

The best solutions, certified