Home » Double diaphragm pneumatic pumps » Diaphragm Pump Phoenix FOOD

Phoenix FOOD diaphragm pumps

Diaphragm pumps are widely used in the food and cosmetics sector thanks to their ability to handle a wide range of fluids, even corrosive, viscous or in the presence of solid bodies.

Phoenix FOOD diaphragm pumps are made with FDA certified construction materials, compliant with the regulations for contact with food or pharmaceutical products and designed to facilitate cleaning and complete maintenance.

The parts in contact with the fluid are exclusively in electropolished AISI 316 and PTFE, both certified for use in contact with any type of food or drug, but also additives or food supplements, animal feed and veterinary drugs.

Phoenix FOOD pumps are able to move fluids with very high viscosities and temperatures that can reach 95°C, minimizing the risk of cross-contamination thanks to the hermetic seal design.

FLUIMAC ATEX diaphragm pumps are made of PP+CF, PVDF+CF, POMc+CF, ALUMINUM and AISI 316.

Application sectors Phoenix FOOD range

Data sheet

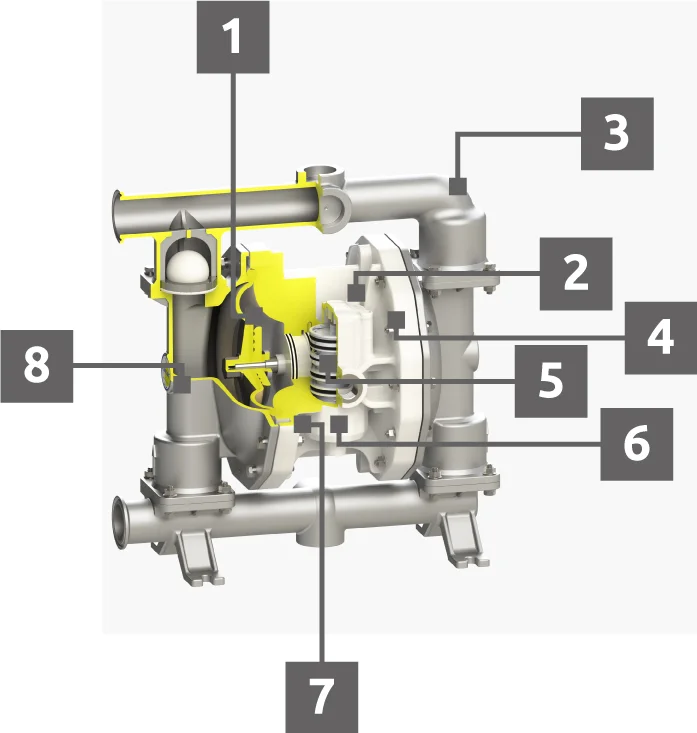

01. Long-life diaphragms ensure consistent performance and longer operation.

02. Efficient pneumatic distributor design results in low air consumption. An unbalanced pilot bushing precisely controls the positioning of the main feed spool to eliminate stall situations and increase efficiency.

03. Fixing screws to prevent leaks and ensure maximum safety.

04. Central body and pneumatic system made of plastic materials for greater chemical resistance in highly corrosive environments.

05. Exchanger and pneumatic bushings made of acetal plastic, which ensures long-term resistance thanks to self-lubrication.

06. The pneumatic distributor is easily accessible from the outside for quick inspection. The system is anti-stall and anti-freeze, and does not require lubrication.

07. Special membrane tightening, designed to minimize wear and increase service life, while providing a tight and secure seal to prevent leaks.

08. Exhaust chamber equipped with double silencer to widen diffusion, reduce freezing and ensure low noise level.

The products of the Phoenix FOOD range

Request a consultation

Do you need support in choosing the pneumatic pump that best suits your specific fluid handling needs?

Fill out the form below and our staff will contact you.

The best solutions, certified