Home » Double diaphragm pneumatic pumps » Diaphragm Pump LOTUS

LOTUS Diaphragm Pumps

The LOTUS diaphragm pump is a master of the art in transferring hazardous chemicals such as acids, caustics and solvents. Constructed from the highest quality materials including PTFE, conductive PTFE, PE, conductive PE and pure polypropylene, the LOTUS AODD pump series offers a reliable and safe solution for a wide range of demanding industrial applications.

Thanks to their versatility and durability, LOTUS pumps are the ideal choice for transferring abrasive liquids, paints, highly concentrated acids and bases, and many other aggressive chemicals.

LOTUS pumps are precision CNC machined, providing solid plastic components that enhance the pump’s strength and durability, while reducing maintenance requirements. Materials such as PTFE, PE and PP enable the pump to withstand even the harshest environments. The solid construction, machined rather than molded, provides precise tolerances, reduces vibration and increases overall stability and durability. Additionally, the high static mass ensures smooth operation with minimal vibration.

Fluimac LOTUS diaphragm pumps handle aggressive and abrasive chemical liquids, ensuring precision and reliability in the sensitive production processes typical of the industry such as etching, cleaning and removal of contaminants, chemical deposition and water treatment.

LOTUS diaphragm pumps ensure the safe and sterile transfer of chemicals essential for the production of pharmaceuticals, maintaining high purity and preventing contamination in the different phases, such as fluid transfer, water treatment, cleaning and sanitization operations up to the precise management of pharmaceutical components.

Application areas of the Phoenix FLAP range

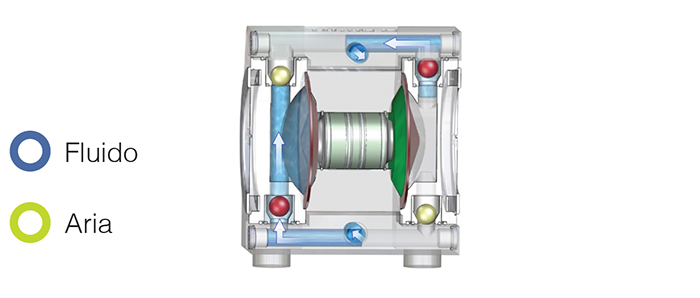

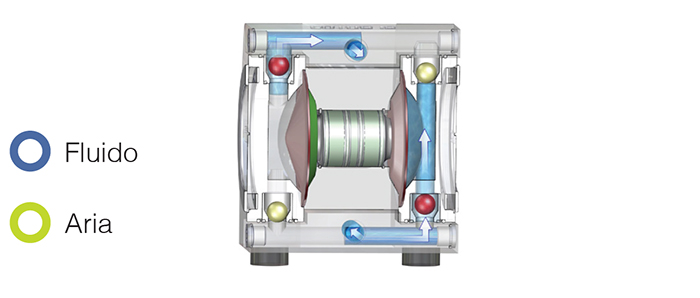

How it works

01. Suction

The compressed air fills the right internal chamber. Thanks to the movement of the opposite membrane, it creates, by lifting the ball of the lower valve, the suction of the incoming liquid. At the same time, the left chamber is in the “discharge” cycle.

02. Delivery

The compressed air fills the left internal chamber. In the opposite chamber, by lifting the ball in the upper valve, it discharges the fluid. At the same time, the left chamber is in the “suction” cycle.

Technical features

The construction materials of the Lotus series are PTFE, CONDUCTIVE PTFE, PE, CONDUCTIVE PE and PURE POLYPROPYLENE. Lotus pumps are suitable for working with hazardous chemicals such as acids, caustics and solvents.

Features and Benefits

01. Made of CNC machined plastic

02. Excellent Performance

03. Increased Safety

04. Reduced Air Consumption

05. Easier Cleaning

06. Reduced Noise Level

07. Reduced Downtime

08. Optimized Hydraulic Flow

09. High Quality

10. Long Life

11. Increased Reliability

12. Applications in Heavy Processes

13. Robust Design with Reinforcement Systems for Better Sealing

Precision CNC Machined

The LOTUS solid plastic components increase the strength and durability of the pump while eliminating many maintenance issues. The LOTUS Series CNC machined PTFE, PE or PP parts can withstand the harshest environments. The LOTUS Series solid plastic block construction is machined rather than injection molded.

CNC technology allows for high precision tolerances, reduced vibration, less risk of leaks and greater stability and durability. The high static mass ensures smooth operation with reduced vibration.

Phoenix LOTUS range products

Request a consultation

Do you need support in choosing the AODD pump that best suits your specific fluid handling needs?

Fill out the form below and our staff will contact you.

The best solutions, certified