Home » Double diaphragm pneumatic pumps » Pneumatic Pulsation Dampeners

Pulsation dampers DAMPER

Diaphragm pumps can generate pulsations in the fluid flow, causing pressure variations.

Pneumatic pulsation dampers are the most efficient system to avoid pressure oscillations during the pump delivery phase. These systems drastically reduce pulsations and water hammers of the fluid, also limiting the vibrations of the diaphragm pump.

The Fluimac pulsation damper works actively with compressed air, automatically setting the correct pressure to minimize pulsations. These dampers require minimal maintenance and are available in the same material configurations as the pumps.

Fluimac DAMPERS are made with cutting-edge technology capable of minimizing the pulsating effect of the flow, up to 90%, and do not require adjustments or pre-loading as they self-adjust, fully adapting to the curve of the fluid arriving in the delivery pipes.

Application areas DAMPER range

How it works

The pulsating fluid of the discharge pushes the diaphragm upwards where it is cushioned by the air in the pneumatic chamber.

The flexing of the diaphragm absorbs the pulsation creating a constant flow.

Significant reduction in pulsation pressure with an average of 70-80% in applications with pressure feedback.

APPLICATIONS

MEASUREMENT AND DOSING: Dampens discharge pressure peaks, increasing accuracy.

FILTER PRESS Increases the efficiency and operating life of filters.

SPRAYING Smooth, consistent spray pattern.

FILLING Eliminates filling errors and splashes.

TRANSFER Eliminates damaging water hammer, safeguarding pipes and valves.

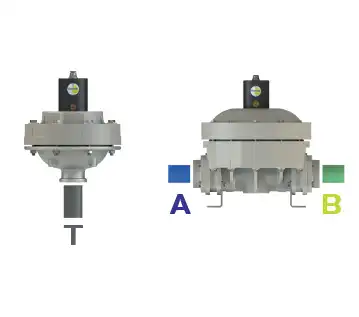

INSTALLATION

PORT POSITION

DAMPER range products

Request a consultation

Do you need support in choosing the pneumatic pump that best suits your specific fluid handling needs?

Fill out the form below and our staff will contact you.

The best solutions, certified