Home » Double diaphragm pneumatic pumps

Double diaphragms pneumatic pumps

PHOENIX RANGE

Pneumatic diaphragms pumps for aggressive liquids

FLUIMAC pneumatic double diaphragms pumps – or pneumatic diaphragms pumps – are recognized as the most flexible pumps in the treatment of aggressive liquids, at variable pressures and flow rates, with a practically unlimited range of applications.

Diaphragms pumps are ideal for handle dirty fluids, with apparently very high viscosities and also with solid parts in suspension.

From the chemical and pharmaceutical sectors to the food, diaphragms pumps are used in many processes that need to transfer liquids, even in the presence of an aggressive environment by the saturation of chemical products.

Double diaphragm pumps for every fluid handling need

Almost any type of liquid, from highly acidic, corrosive or alkaline, paints, glues, high viscosity liquids up to 50,000 CPS, food products, can be handled thanks to Fluimac Phoenix pumps.

Choosing the most suitable pump for specific application needs means evaluating and considering various factors that allow you to optimize performance, extend the life of the pump and minimize maintenance costs.

The parameters analysed are:

- The composition of the fluid to be pumped, its viscosity and the solids contained

- Pumping capacity in relation to the desired flow rate

- The suction and pressure conditions

Phoenix range

Standard Phoenix diaphragms pumps

Phoenix double diaphragms pumps can pump a wide range of fluids, including viscous, corrosive, abrasive, containing suspended solids, without the risk of damage or significant mechanical wear, reducing the risk of dangerous fluid leaks thanks to the absence of mechanical seals.

Phoenix ATEX diaphragms pumps

ATEX diaphragms pumps are designed to operate in environments with potentially explosive atmospheres. They resist to corrosion and wear and are compatible with dangerous fluids, minimizing the risk of sparks.

Phoenix FOOD Diaphragms Pumps

FOOD double diaphragms pumps are specifically designed and built to meet the standards required for use in applications involving the food industry. They offer versatility, efficiency, and reliability in manufacturing environments where product purity and quality are of utmost importance and where a wide range of viscosities and solids must be handled.

Phoenix ACCURATE diaphragm pumps

Accurate Phoenix pneumatic pumps could work by a remote control, necessary for precision applications such as dosing, which allows them to be controlled or managed remotely, without the need for direct physical interaction with the operator, reducing risks and increasing accuracy.

STEEL Phoenix diaphragm pumps

Phoenix Steel ouble Diaphragm Pumps with SS central block, combine the benefits of double diaphragm pumps with the superior properties of stainless steel, offering highly efficient, reliable and hygienic pumping solutions, even with low or high temperature.

FLAP Phoenix Diaphragm Pumps

Phoenix Flap Pumps with clapet valves solve the most common challenges in difficult applications: sump applications, mine dewatering, food applications and any liquid application involving solids.

LOTUS Diaphragm Pumps

Thanks to their versatility and resistance, they represent a reliable and safe solution for a wide range of demanding industrial applications, reducing the need for maintenance.

PIEZO Diaphragm Pumps

Specifically designed for environmental remediation applications, it is an easily transportable pneumatic system, designed to be installed in wells with a minimum internal diameter of 4″ and at a depth of 80m.

QUALITY

100% of the pumps are tested with water after assembly.

SAFETY

Atex certification in all versions: plastic pumps made of conductive materials.

FLEXIBILITY

Possibility of different connections and port position.

The range of Phoenix double diaphragm pumps is the perfect solution for handling aggressive liquids, even viscous or in the presence of impurities.

Scarica il catalogo di gamma

OPERATION OF THE DIAPHRAGM PUMP

How do diaphragms pumps work? What are the benefits?

Pneumatic double diaphragms pumps are considered among the most efficient pumps, also thanks to their simple operation, and are mainly used for the movement of liquids.

Pneumatic double diaphragms pumps are composed of two separate and opposing internal chambers, one for the compressed air and the other for the pumped liquid. The only parts in contact with the liquid are the membranes, which are located between two pumping chambers and are activated by the pneumatic distributor, and the valves, which guarantee total passage in both suction and delivery.

Double diaphragms pneumatic pumps are designed and built to handle a wide range of fluids, acid or alkaline, more or less viscous and with solid parts in suspension.

Heavy applications, such as high humidity environmental, acidity in the air or potentially explosive atmospheres, do not create any type of problem for this type of pump, which refers to the European Directive 2014/34/EU.

There are no limits of use regarding liquids, unlike other types of pumps: acids, alkalines, muds, paints, solvents, with solids in suspension up to a diameter of 10 mm, ceramic liquids or abrasive liquids. The diaphragm pump can be used also for dry operation, in self-priming, or by using them submerged in the fluid or for mixing liquids.

Fluimac diaphragms pumps, a guarantee of excellence

The construction method of Fluimac double diaphragms pumps gives them stability and safety, guaranteeing safe operation without the need for lubricated air. The operation speed can be adjusted, as can be regulate the flow-rate for unprecedented versatility of use.

The quality of the materials used in the construction of the various models of Fluimac diaphragms pumps makes these pneumatic diaphragms pumps suitable and certified for use in dangerous areas highly saturated with aggressive products.

Double diaphragm pumps are perfect for the safe handling and dosing of dense, chemical, corrosive and viscous liquid products. They are therefore suitable for handling solvents, inks, paints, fuels, chemical products and abrasives. But also explosive or flammable liquids, as well as any type of food or pharmaceutical fluid.

Fluimac implements a rigorous choice of components used in the construction parts of pneumatic pumps, preferring certified partners and materials. This, combined with construction techniques and careful design, has allowed us to create ATEX certified diaphragm pumps, suitable for working in highly dangerous areas, and air pumps with FDA certification of materials for safety in the food, pharmaceutical or cosmetics sectors.

The standard Phoenix pumps, with new air distribution system and new valve technology, are made of PP, PVDF+CF, Aluminum and SS AISI 316.

Phoenix ATEX double diaphragms pumps are made of PP+CF, PVDF+CF, Aluminum and SS AISI 316.

The Phoenix Food double diaphragms pumps, built with materials FDA compliant regulations, are specifically dedicated to the food, pharmaceutical and cosmetics industries with parts in contact with fluids made exclusively in electro-polished SS AISI 316 and PTFE.

By relying on Fluimac in choosing a double diaphragm pump model you will be sure of being able to work in complete safety. Guaranteeing the quality and correct and prolonged operation of the double diaphragms pneumatic pump, so as to be able to maintain high production standards of your company.

Our sales team offers support in choosing the fluid handling solution best suited to the specific need based on the fluid to be treated, the sector and the pumping needs.

Contact our team to receive all the information and define the double diaphragms pump most suitable with your needs.

Damper pneumatic pulsation

Damper pneumatic pulsation dampeners

The Damper range of pneumatic pulsation dampeners allows you to reduce flow pulsations and vibration in the pumping line. This improvement in flow stability leads to several operational and maintenance benefits.

Pulsation dampeners DAMPER FOOD

They improve the efficiency and operational safety of diaphragm pumps, especially in FDA-regulated sectors, ensuring stable and precise operation, minimizing pulsations.

Damper ATEX pneumatic pulsation dampeners

The use of pulsation dampers in ATEX environments improves plant safety and reliability, while also contributing to operational efficiency and investment protection in critical equipment and infrastructure. Their implementation is an important step in risk management in areas with potentially explosive atmospheres.

Phoenix range accessories

AIR REGULATION KIT

Adjust and set the air pressure and flow rate with a filter-regulator group, pressure gauge and air valve unit.

VALVOLA ON/OFF

Remotely start and stop with a solenoid or pneumatic valve for the pump’s air line.

STROKE COUNTER

Counting the number of strokes connected to a controller allows various types of monitoring.

FLUID-GUARD: DIAPHRAGM FAILURE DETECTION

The Leak Detector provides a signal and the pump can be shut down when diaphragms fail.

PNEUMATIC BATCH CONTROL

Pneumatic batcher can control any FLUIMAC AODD pump allowing you to set the cycles amount and count the strokes.

ELECTRONIC BATCH CONTROL

Electronic batcher can control any FLUIMAC AODD pump allowing you to set the cycles amount and count the strokes.

BASKET STRAINER FILTERS IN PP

Installed on the suction of the pumps, protects them from suspended solids and impurity.

PRESSURE BOOSTER

Where the line pressure is not enough, this system doubles the inlet pressure to supply correctly the air to the pump.

STAINLESS STEEL TROLLEY

Makes the pump transportable.

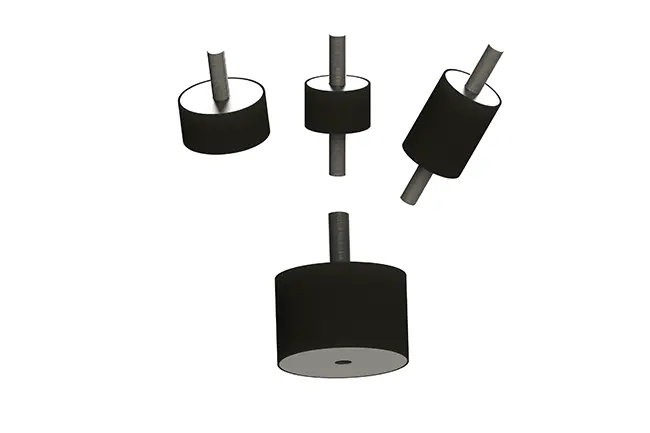

ANTI-VIBRATION FEET KIT

Reduces the normal vibrations of a diaphragm pump.

PP, PVDF, ALUMINUM AND STAINLESS STEEL NOOZLE

Dispenser to delivery control and batching.

REINFORCED PVC HOSE

With metal reinforcement for suction/discharge, also food-grade.

BALL FOOT VALVE

Realized in PP and PVDF. Size available 1” - 1”1/4 - 1”1/2 - 2”. Used to prevent the suction hose from emptyng.

PP, PVC, STAINLESS STEEL VALVES, FITTINGS AND CONNECTIONS

FLANGED CONNECTIONS KIT

To transform a pump with BSP type connections into flanged ones.

WALL FIXING BRACKET

Wall fixing bracket for diaphragm pumps, for all sizes.

Request information

Do you need support in choosing the double diaphragms pump most suitable with your specific fluid handling needs?

Fill out the form below and you will be contacted by our staff.

The best solutions, certified