Home » Air motors

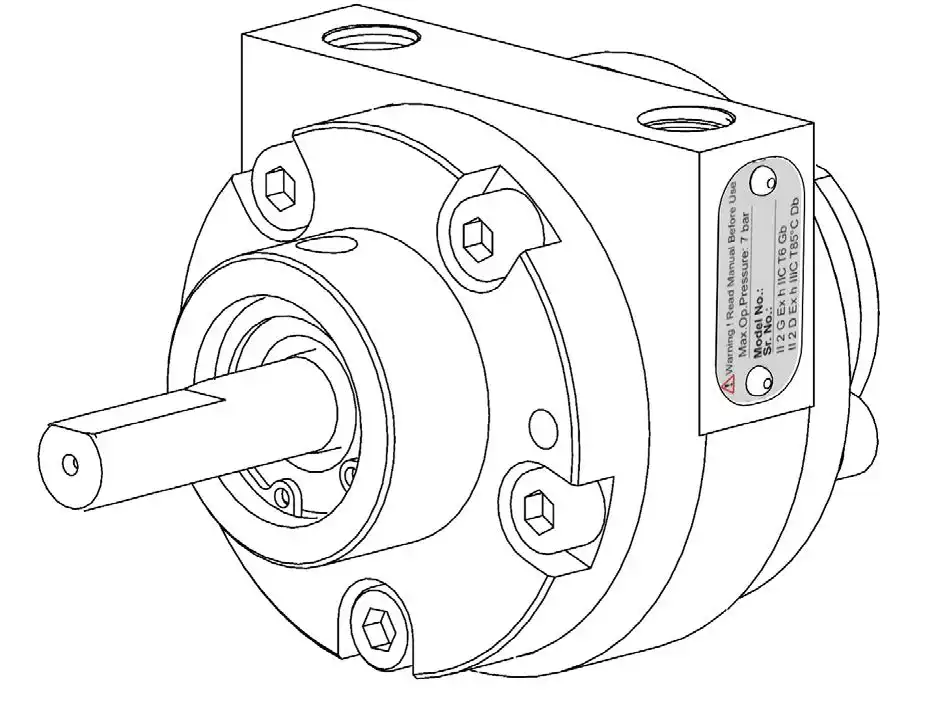

Air motors

Air motors represent a versatile and safe solution for many mixing and fluid handling applications, offering significant advantages in terms of safety and regulation; they also require reduced maintenance compared to electric motors.

Fluimac air motors can operate without interruption 24 hours a day, start and stop repeatedly in contexts where electric motors would risk overheating.

Fluimac air motors are also particularly suitable for high temperature environments and classified Atex zone 1 and zone 2, where standard electric motors are not permitted.

Fluimac air motors can be supplied in both lubricated and oil-free versions.

Air motors equipped with in-line lubricators offer extended life, increased efficiency and protection from corrosion caused by dirty or moist supply air. They operate at a maximum pressure of 7 bar.

Lubrication-free air motors are intended for applications where the working environment is sensitive to pollution and traces of oil mist in the exhaust gases are not permitted.

They are ideal for clean environments such as food processing and pharmaceutical manufacturing; they operate at a maximum pressure of 5 bar.

Application sectors of air motors

Characteristics

Fluimac air motors are designed for applications where direct drive motors can be used and offer numerous advantages over electric motors. Fluimac air motors have a continuous duty rating, meaning the motor can run continuously or can start and stop repeatedly in applications where electric motors can burn out. Air motor operation is particularly suitable for high-temperature and hazardous environments where standard electric motors are not permitted.

Main features

01. Variable speed

02. No electric sparks

03. Instant reversibility

04. High power

05. Compact and portable

06. Minimal maintenance

07. Works in all positions

08. Low impact starts

09. Self-sealing vanes

10. Mounting flexibility

SELECTION:

Air motors are different from other power sources. These unique operating characteristics must be taken into consideration when selecting an air motor for a particular job.

It is easy to change the power and speed of an air motor by throttling the air inlet.

The best rule of thumb for selecting an air motor is to choose one that provides the necessary power and torque using only two-thirds (2/3) of the available line pressure.

The entire air line pressure will then be available for surges and starting.

LUBRICATED OR WITHOUT LUBRICANT

Air motors operating with in-line lubricators have the advantage of longer life, better efficiency and surface finishes protected from incoming dirt or moist air.

Lubricated motors operate at a maximum pressure of 7 bar.

Applications in which the working environment around the engine is sensitive to pollution and traces of oil mist in the exhaust are not permitted to require lubrication-free engines. These motors can operate completely without lubrication and do not discharge any contaminants into the atmosphere. They are ideal for applications that require clean environments such as food and pharmaceutical processing.

Lubrication-free motors operate at a maximum pressure of 5 bar.

Fluimac air motors

Scarica il catalogo di gamma

Request a consultation

Do you need support in choosing the air motors most in line with your specific fluid handling needs?

Fill out the form below and you will be contacted by our staff.

The best solutions, certified